Bowser Drive Shaft Construction

HO New Orleans Style Trolley

by Charles R. Hentz

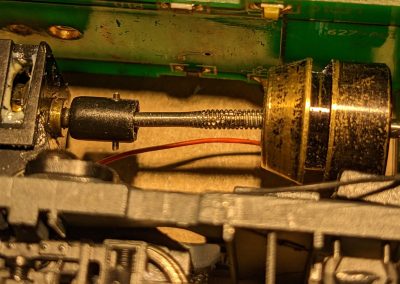

The original drive shaft was made of plastic with a hexagonal ball that wore out quickly. To make a metal replacement, take a 2-56 round head machine screw that is 3/4 inch long. Protect the threads with shrink wrap and place in the chuck of an electric drill with the head end out about 3/8 inch. While the screw is rotating in the drill, use a grind stone to remove the side of the head and some of the threads to get the shaft width to 1.4 mm leaving the slot untouched. A vernier caliper is ideal for this measurement.

Now place two hex nuts near the threaded end locked tightly together. This will keep the nuts from moving as you file each surface and you will be making an extra nut with the correct size for a future shaft. Using a pin vise to hold the screw steady and a mill file to take exactly .5 mm (point five) off one flat side of the hex nuts. Then take .5 mm off the other parallel side. You need to get all parallel sides to be 3.5 mm apart to fit into the flywheel. The original hex nut was 4.5 mm wide from flat side to flat side. After one pair of sides are filed, you must be careful to file the other remaining sides at an angle of 60 degrees from the first pair. A wood block placed next to the handle of the pin vise can act as a tool rest and also be marked with a line showing the correct angle.

When you are finished with the hex nuts, remove one and keep for a future drive shaft. Position the remaining hex nut about 2 mm or 1/16 from the end. Now apply a drop of blue Loctite on the nut to keep it from moving. After this is set, round off all sharp corners and edges on the single hex nut to allow easy movement in all directions while in the flywheel.

The last step is to secure a straight pin in the slot. Place a pin in the slot and try to pinch the sides of the slot closed with vise grip pliers. Then solder it in place. Nipping off each side evenly to a total length of 4 mm will allow some extra metal to protrude outside of the slot in the truck.

This new metal drive shaft can be installed by removing two screws holding the truck in position. By placing the hex end of the drive shaft all the way into the fly wheel and pushing the truck away from the flywheel, the pin end can be placed into the slot of the truck with a little effort. If this does not fit, carefully grind some metal off the hex end until you can get this to slide in. About 1 mm or 1/32nd inch should be enough. Then return the truck to the original position and replace the screws. Now test for full motion of the fly wheel and truck. You should now be able to have years of smooth operation since this is made of steel and not plastic.